Horizontal Lump Wood Charcoal Kiln Carbonization Furnace Stove

Price 142449.0 INR/ Unit

Horizontal Lump Wood Charcoal Kiln Carbonization Furnace Stove Specification

- Product Type

- Horizontal carbonization furnace

- General Use

- Industrial

- Material

- Charcoal

- Production Capacity

- 1-5 Ton

- Product Shape

- Customized

- Weight (kg)

- 400 Kilograms (kg)

- Type

- Briquette Machines

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Cooling System

- Air Cooling System

- Voltage

- 380/customized Volt (v)

- Motor

- AC Motor

- Briquette Size

- customized

- Dimension (L*W*H)

- 1.5*1.2*1.4 Meter (m)

- Feature

- Energy Saving

- Color

- Other

- Warranty

- 1 year

Horizontal Lump Wood Charcoal Kiln Carbonization Furnace Stove Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Paypal, Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- container

- Main Export Market(s)

- Western Europe, Middle East, Africa, Asia, Australia, Central America, North America, South America, Eastern Europe

- Main Domestic Market

- All India

- Certifications

- CE,ISO,CCC

About Horizontal Lump Wood Charcoal Kiln Carbonization Furnace Stove

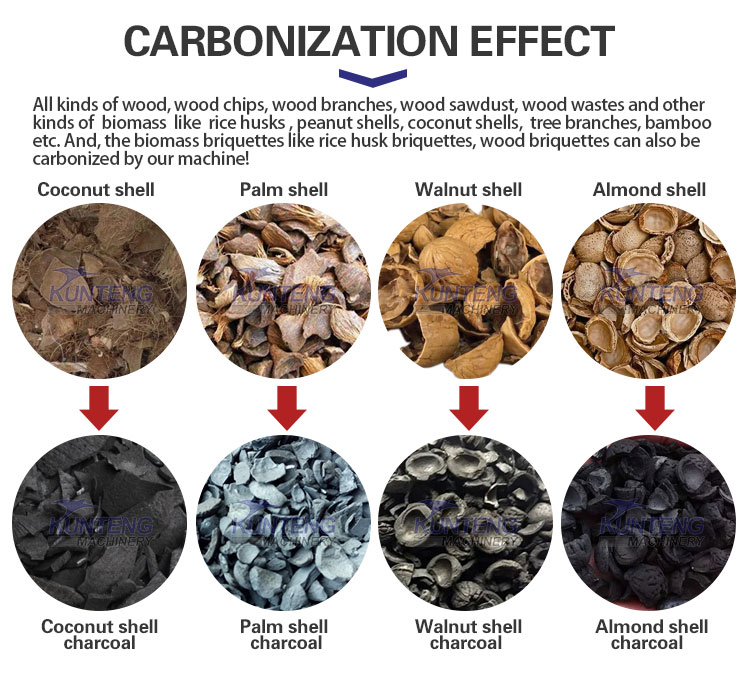

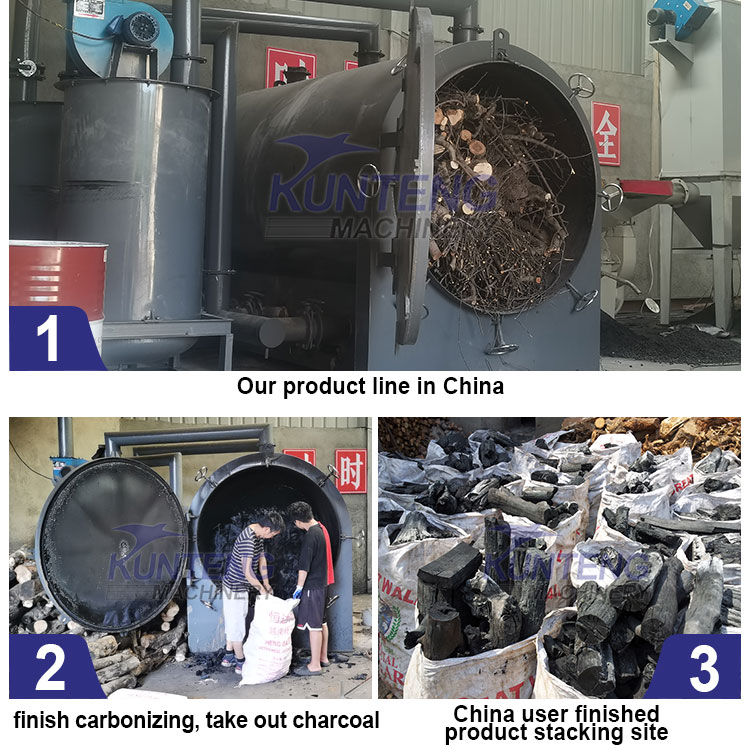

Firstly, palm shell, coconut shell, wood, bamboo and other biomass are carbonized into charcoal by carbonization furnace and enter hoister and storage tank. According to customer's raw material, you can choose continuous carbonization furnace, horizontal charcoal making stove and hoisting carbonization furnace.

Secondly, charcoal can be crushed into charcoal powder by dust-free grinder.

Thirdly, charcoal powder are stirred by double shaft mixer and mixer.

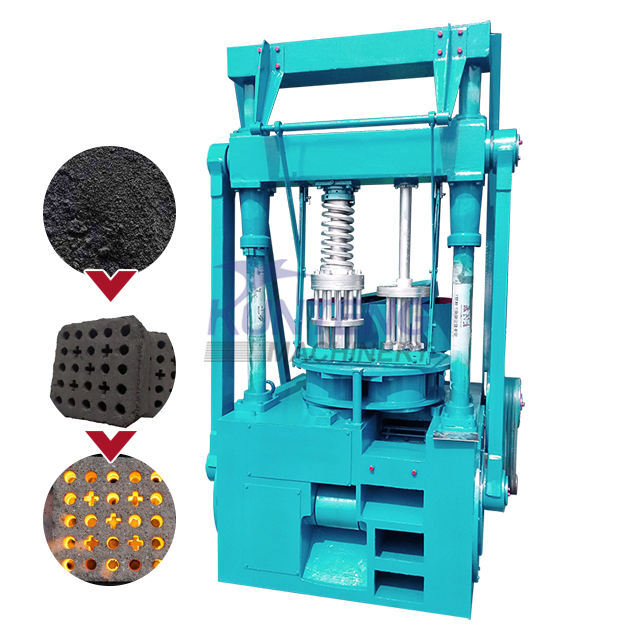

In the end, charcoal powder can be formed into ball, cylinder, tables and cubic by briquette machine and enter the dryer by drying.

The whole carbonization furnace, lump charcoal kiln and wood charcoal stove production line are fully automatic.

CONTINUOUS CARBONIZATION FURNACE

HOISTING CARBONIZATION FURNACE

1. Over 100 employees, 98% professional technical personnel;

2. Factory size over 10,000 square meters;

4. Customize Production Line;

Pre-sale

1. According to your needs, select right model for you.

2. According to your special requirements, design customized solution and manufacture customized products for you.

3. Welcome your visit.

Sale

1. Sign contract, pay deposit, we arrange production.

2. Product acceptance.

3. Help you formulate construction scheme.

After-sale

1. Assign engineer service for you on-site freely.

2. Install and adjust device, train how to operate.

3. After installation, leaving 1-2 technical staff to help you on-site production, until achieve customer satisfaction.

A:We are a 15 years factory, all our machinery are manufactured by ourselves, factory direct sales, product quality and after-sales service can be guarantee.

Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year. Our company is located in Zhengzhou Henan province, China, you can come here by air or train. The nearest airport is Zhengzhou Xinzheng International Airport, and the Airport Code is CGO. We will pick you up at airport. Welcome to visit our factory.

Q: What is the Quality of your products?

A: KUNTENG Group products come with best quality, and our products passed CE certification, exported to lots countries around the world, such as Australia, Malaysia, India, Italy ,Indonesia, Vietnam, Philippines, Korea, Brazil, Argentina, Russia, South Africa, etc. You can rest assured with the quality absolutely.

Q: What is the Installation of your products?

A: KUNTENG Group has several experienced technicians with passports ready to go for installation, when installation service is needed, the client should pay for technicians' round way air tickets, food and lodging, most importantly to guarantee the technician's safety.

Q: How long is the Warranty of your equipment?

A: Our warranty period is one year generally.

Q: What should I provide to get the suitable quotation?

A: 1.What is the raw material for the production line?

2. What is the capacity per hour you required?

3. What is the maximum input size of the raw material?

4. What is the output size and application for the final product?

You can send inquiries from this page.Once we get your answers,we can provide you the best quotation immediately.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Charcoal Making Machine Category

Briquette Charcoal Briquette Making Machine

Price 340658.0 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 YEAR

PLC Control : Yes

Feature : Low Consumption, Energy Saving, Compact Structure, High Efficifiency, Automatic Feeding System, Automatic Discharging System, Customized Accessories

Product Type : Coal powder forming machine

Honeycomb coal briquetting machine, charcoal forming machine

Price 340658.0 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 YEAR

PLC Control : Yes

Feature : Low Consumption, Energy Saving, Compact Structure, High Efficifiency, Automatic Feeding System, Automatic Discharging System, Customized Accessories

Product Type : Honeycomb charcoal briquette machine

Coal Powder Briquette Making Machine

Price 431697.0 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 year

PLC Control : Yes

Feature : Low Consumption, Energy Saving, High Efficifiency, Compact Structure, Automatic Feeding System, Automatic Discharging System, Customized Accessories

Product Type : Coal briquetting machine

Industrial hydraulic block coal forming machinery coal powder mineral powder hydraulic machinery coconut shell carbon powder compression forming machinery

Price 870093.0 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1year

PLC Control : Yes

Feature : Low Consumption, Energy Saving, Compact Structure, High Efficifiency, Automatic Feeding System, Automatic Discharging System, Customized Accessories

Product Type : charcoal Briquette Making Pressing Machine

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry