Industrial Be-er Waste Malt Dryer Machine Cassava apple Grape Pomace Drying Machine Food Waste Rotary Dryer

Price 869074.0 INR/ Unit

Industrial Be-er Waste Malt Dryer Machine Cassava apple Grape Pomace Drying Machine Food Waste Rotary Dryer Specification

- Product Type

- Drum Drying Equipment

- General Use

- Chemicals Processing, Plastics Processing, Food Processing

- Type

- Other

- Weight (kg)

- 2000 Kilograms (kg)

- Computerized

- Yes

- Automatic

- Yes

- Touch Screen

- Yes

- Control System

- PLC Control

- Surface Treatment

- Other

- Voltage

- 380V or customized Volt (v)

- Dimension (L*W*H)

- 800*800*8000 Millimeter (mm)

- Feature

- High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency, Simple Control, Stable Operation

- Color

- customized

- Warranty

- 1year

Industrial Be-er Waste Malt Dryer Machine Cassava apple Grape Pomace Drying Machine Food Waste Rotary Dryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Letter of Credit (L/C), Paypal, Telegraphic Transfer (T/T)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 15 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- container

- Main Export Market(s)

- Asia, Australia, Central America, Western Europe, Middle East, Africa, North America, South America, Eastern Europe

- Main Domestic Market

- All India

- Certifications

- CE,ISO,CCC

About Industrial Be-er Waste Malt Dryer Machine Cassava apple Grape Pomace Drying Machine Food Waste Rotary Dryer

2.Less Fuel Consumption

3.Low Drying Cost

4.High Temperature Resistance

5.Operate Steadily and Simple Structure

6.Strong overload Resistance

Working principle:

Advanced Drying Technology for Multiple Industries

This rotary dryer is specifically designed for diverse industries, including food, plastics, and chemical processing. Its high-performance drying chamber ensures uniform moisture removal from materials such as waste malt, cassava, apples, and grape pomace. Whether scaling up for industrial needs or seeking energy-efficient solutions, this machine offers stable operation and adaptability to different drying requirements.

Effortless Operation and Intelligent Control

Featuring a modern PLC control system and intuitive touch screen interface, the dryer allows for simple and precise monitoring of the drying process. Automation minimizes manual intervention, while the clear display informs operators of temperature, humidity, and duration. This enables users to fine-tune operations for optimum output and consistent product quality.

FAQs of Industrial Be-er Waste Malt Dryer Machine Cassava apple Grape Pomace Drying Machine Food Waste Rotary Dryer:

Q: How does the Industrial Be-er Waste Malt Dryer Machine operate?

A: The drying machine utilizes a rotary drum mechanism powered by a PLC control system and touch screen interface, which automates and monitors the drying process for efficient and uniform moisture removal. Operators can adjust temperature, humidity, and timings to suit specific products like malt, cassava, or grape pomace.Q: What materials can this rotary dryer process?

A: This dryer is ideal for drying a variety of materials, including waste malt from brewing, cassava, apple and grape pomace, food waste, as well as various items in chemical and plastics processing industries.Q: When should the dryer be used in processing?

A: Use the dryer after raw materials have been prepared and require moisture reduction before further processing or packaging. It is especially crucial in food, chemical, and plastics production to enhance storage life and product quality.Q: Where can this drying machine be installed?

A: The machine can be installed in any industrial facility focusing on food, plastics, or chemical processing. Ensure there is appropriate space for the machines 8000mm length and access to 380V power or your preferred customized voltage.Q: What benefits does this dryer provide over conventional dryers?

A: This machine features ECO-friendly design, high drying efficiency, lower noise, reduced energy consumption, automated controls, and simple operation. Its stable and computerized operation means greater productivity and cost savings.Q: How is the drying process controlled and monitored?

A: A PLC control system with a touch screen panel allows users to manage all key parameters including temperature, rotation speed, drying time, and product monitoring, ensuring consistent and tailored results for various materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dryer Machine Category

Continuous Vegetable Dehydrator Large Scale Chili Chili Pepper Dryer Industrial Red Chili Drying Equipment

Price 2196846.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Product Type : Mesh belt dryer

Computerized : Yes

Feature : High Efficiency, Simple Control, Stable Operation, High Performance, ECO Friendly, Low Noise, Lower Energy Consumption

Fruit Dried Fruit Drying Machine

Price 425774.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Product Type : Box type dryer

Computerized : Yes

Feature : Low Noise

Tray drying box coal dryer large capacity drying equipment charcoal dryer

Price 426168.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Product Type : charcoal dryer

Computerized : Yes

Feature : High Efficiency, Simple Control, Stable Operation, High Performance, ECO Friendly, Low Noise, Lower Energy Consumption

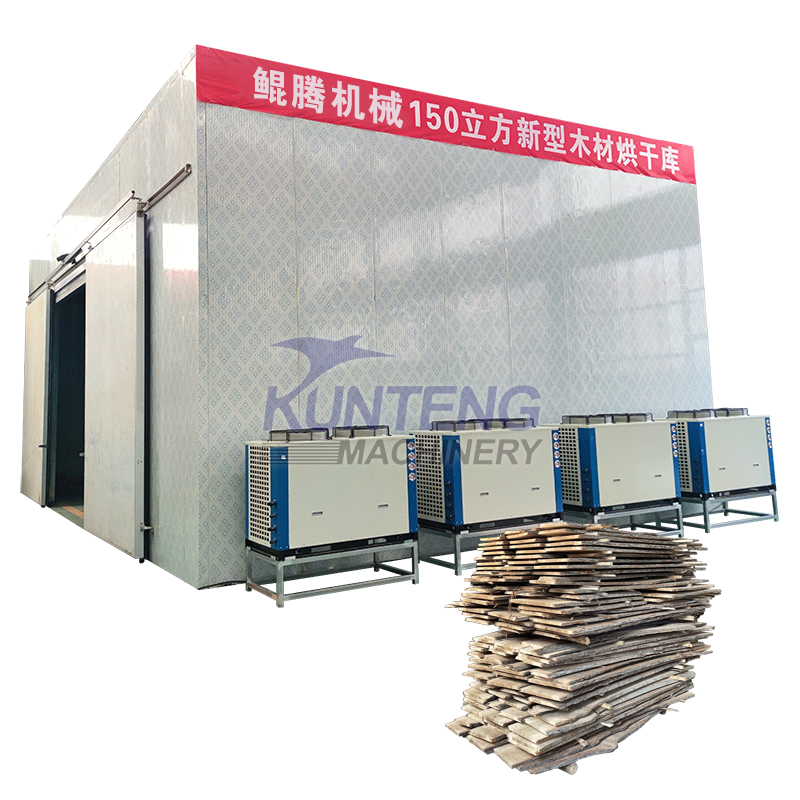

High Capacity New Pattern Timber Dryer Kiln Pallets Wood Drying Chamber Wood Drying Equipment

Price 2154949.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Product Type : Drying Oven

Computerized : Yes

Feature : Simple Control, ECO Friendly, High Efficiency, Stable Operation, Lower Energy Consumption, High Performance, Low Noise

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry